PRODUCTION – RESEARCH AND DEVELOPMENT

The production technology of KAMA CRANES is always renewed according to developments in the sector. All components are produced according to needed design and quality. The material structure of components are always checked and confirmed for the suitability of the design requirement.The cranes are tested by the different operators in different working conditions before the delivery of the crane.

Because of high operating expenses we produced handling machines powered by electric motor which is also supported by Tubitak, The Scientific and Technological Research Council of Turkey for our customers. By receiving positive feedbacks for our products from our customers, we increased our production capacity and succeeded in the production of new high quality products by combining our 40-year-experience with scientific engineering calculations and with a more than 100 trained and professional employees.

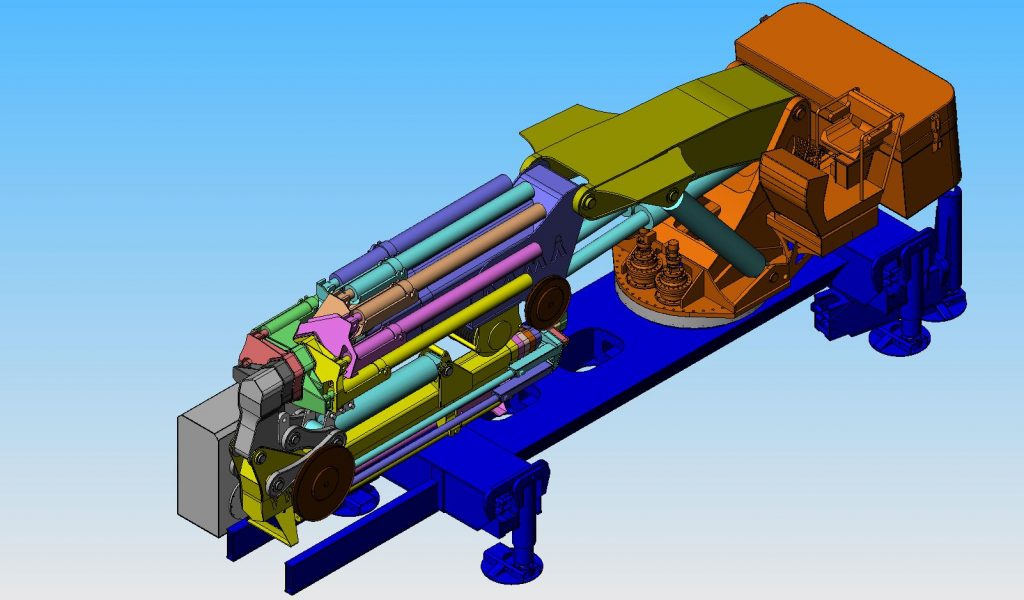

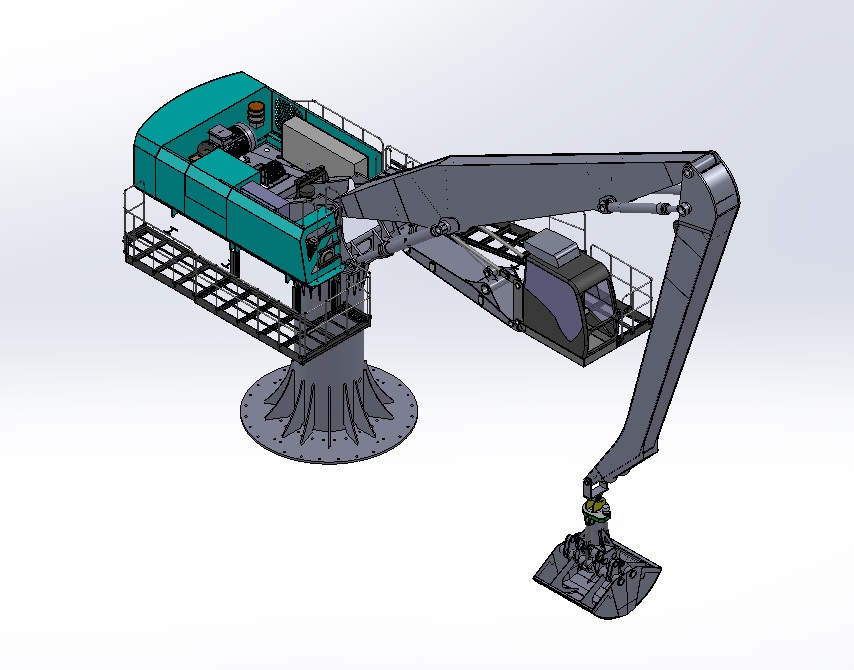

Industrial Design

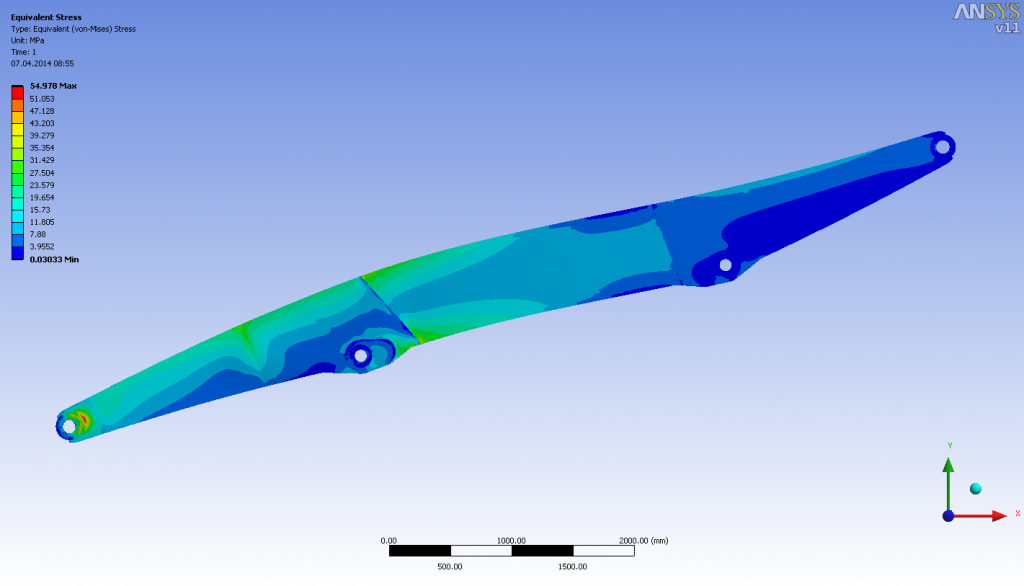

- The design of our cranes is made by our engineers who are professional in it. In a process of design drawing, necessary weight controls are estimated in a computer environment. Cranes are designed and tested according to DIN 15018 norm and H1B3 class.

- In our cranes’ steel construction high resistant steel sheets, that are internationally among organizations accredited and tested in laboratories, are used.

- Crane’s rotation around its axis is supported by a double row or a single row slewing ring, a pinion gear, a planetary gearbox, and a hydromotor. Our cranes rotation around it’s axis is infinite.

- All connection holes in the crane are concentric and processed in the borwerk workbench. The connection shafts used at joint places of the crane are produced from SAE 4140 material, hardened 50-55 HRC with heat treatment and grinded.

- Components used in the hydraulic system are manufactured by ISO 9001 certified companies.

- Cylinder tubes are St 52,3 quality and manufactured from seamless steel drawn material, and their inner surfaces are honed at H8 tolerance. Piston rods are manufactured Ck 45 quality material, and covered with 50 micron hard chrome at the diameter, and their surface is grinded at f7 tolerance. Sealing components used in the hydraulic cylinders are manufactured by ISO 9001:2015 certified companies, and piston seals are manufactured of compact seal; real seals of polyurethane; O’rings of hydraulic liquid, and rubber material not affected by the pressure and temperature.

- When all metal components of cranes are cleaned, they are given to a lining resistant to corrosion. On to this lining an atmosphere conditions resistant dye is applied.